Nanosheets are two-dimensional structures that could bring modern innovations to exceed their current capacities. These materials are layered, with each sheet stacked on the other. The materials are made of crystals that could be separated prior to further use in other applications.

Delaminating Nanosheets

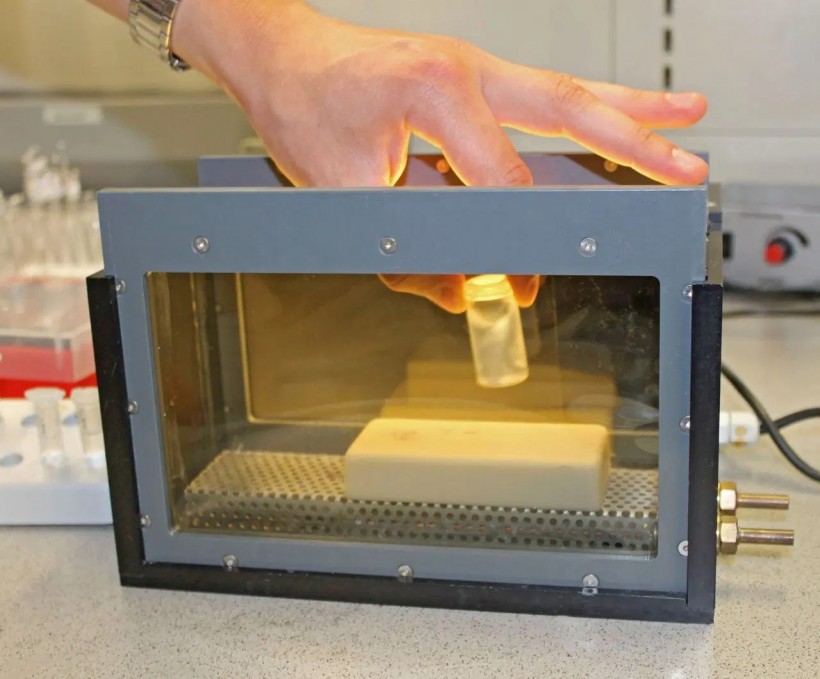

(Photo: UBT / Chr. Wißler)

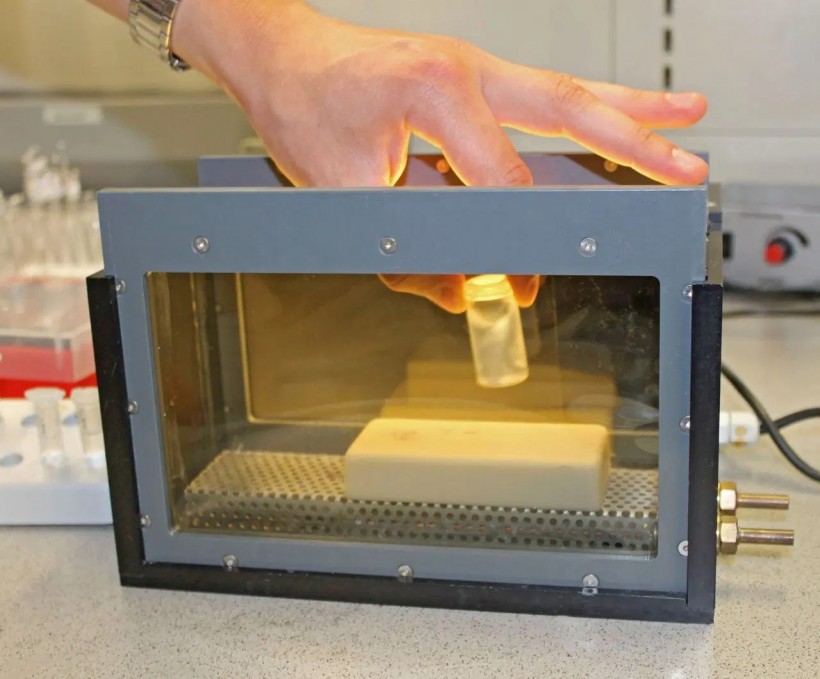

(Photo: UBT / Chr. Wißler)

Layered crystals after osmotic swelling

Layered crystals after osmotic swelling

Nanosheets could work effectively on various filtering techniques, including gas barriers and the division of gas mixtures. In a new study, scholars from the University of Bayreuth created a novel approach to let the nanosheets delaminate better than they could. With this method, the material could be equipped for large-scale industrial processes,

The team was able to carry out the challenging disassembly of the particular nanosheets through a non-destructive and eco-friendly approach. The first research showed how crystals from a zeolite sheet could be utilized for broader applications.

Bayreuth's Bavarian Polymer Institute specialist Josef Breu led the team behind the new delamination procedure. One of the main improvements exhibited by the process is that the isolated materials contained in the nanosheets were not damaged during the experiments. Moreover, PhysOrg reports could modify the structure in an environment with a normal room temperature.

Two-dimensional nanosheets contain an electrostatic force that is a 'glue' to the layered crystal materials. To have these components become usable for other applications, the adhesion coming from electrostatic force must be eliminated, resulting in the layers detaching from one another.

Osmotic Swelling Successful on Zeolite Crystal-Based Nanomaterial

A common approach to performing this type of delamination is osmotic swelling. This method forces nanosheets to break from layers through certain molecules, dissolved ions, and water solutions.

However, osmotic swelling could only cater to specific crystallized materials, including titanates, niobates, and some clay materials. The most promising material, the zeolite crystals, has not been observed with an effective outcome yet with osmotic swelling.

The Bayreuth team was the first to deploy gentle osmotic swelling to ilerite crystals. These objects are categorized under the zeolite group and offer good membranes for various applications.

The authors applied sugar molecules in the gaps between the nanosheets while a separate step produced water to part layers of the structure. Gradually, the spaces in between the sheets grew larger. Once a certain scale is achieved, each layer is pushed horizontally and in various directions.

After drying, multiple nanosheets will be produced from the previously intact structure. The outcome is similar to how playing cards are stacked but overlaps the edges and has few visible gaps. The diameter of nanosheets per piece becomes 9,000 times greater than their thickness.

The authors suggest that this technique would work the same way when applied to a larger number of surfaces. Each of the nanostructures embedded on the surface counterbalance each other. In addition, the gaps are not on top of each sheet, preventing any direct penetrations from external materials such as ions, molecules, and even light.

The results could help industries that require better food packaging designs, battery development, and other optoelectronic-based approaches. The study was published in Science Advances, titled "Nematic suspension of a microporous layered silicate obtained by forceless spontaneous delamination via repulsive osmotic swelling for casting high-barrier all-inorganic films."

RELATED ARTICLE: Novel Approach to Formulate SARS-CoV-2 Vaccines Developed with Protein Nanoparticles

Check out more news and information on Nanotechnology in Science Times.