Engineers from the University of Wisconsin-Madison have created a lightweight nanofiber material that outperforms extensively used equivalents, such as Kevlar fabric and steel plates, in guarding against high-speed projectiles like space debris or bullets.

Lead researcher and UW-Madison assistant professor of engineering physics Ramathasan Thevamaran said that their nanofiber material exhibits protective properties that surpass other similar materials and is much lighter. The novel material is better than existing bulletproof technology.

Novel Lightweight Nanofiber Material Protects Against Space Debris and Better Than Existing Bulletproof Technology

Mixing Carbon Nanotubes With Kevlar Nanofiber

Thevamaran and his team detailed the new nanofiber material in a paper, titled "Extreme Dynamic Performance of Nanofiber Mats under Supersonic Impacts Mediated by Interfacial Hydrogen Bonds," published in the journal ACS Nano.

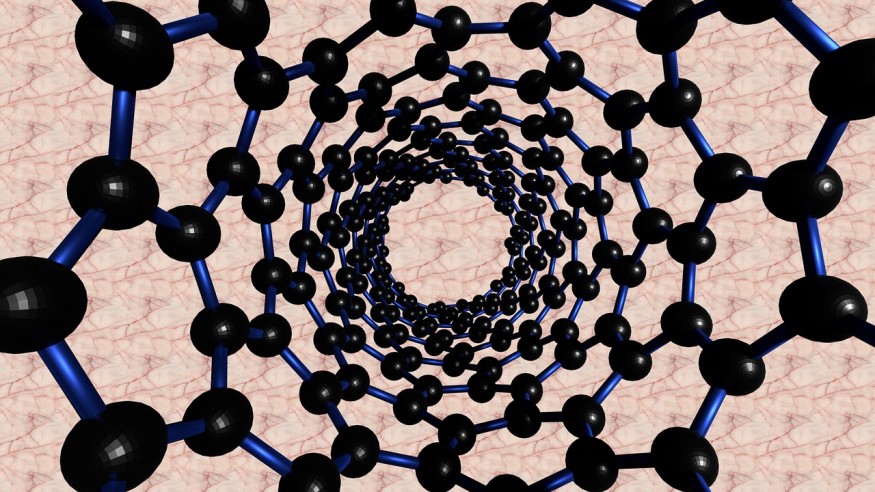

Phys.org reported that Thevamaran and postdoctoral researcher Jizhe Cai mixed multi-walled carbon nanotubes with Kevlar nanofibers to create the new material. Carbon nanotubes are carbon cylinders that are only one atom thick in each layer. But after mixing the two materials, they came up with nanofiber materials that are notably superior at dissipating energy from the impact of high-speed projectiles.

Researchers said this new technology lays the foundation for using carbon nanotubes to make lightweight, high-performance armor, like bulletproof vests and shields around a spacecraft to protect the person better or mitigate damage from micro debris moving faster than the speed of sound.

Thevamaran added that nanofiber materials are a good medium to create protective equipment because they have outstanding toughness, strength, and stiffness than microfiber materials. More so, carbon nanotubes have shown their energy absorption capabilities in other applications, and engineers have demonstrated in the recent study that they could further improve their performance.

The team found the perfect combination of Kevlar nanofibers and a tiny amount of carbon nanotubes that resulted in hydrogen bonds between fibers. These bonds caused a dramatic leap in the overall performance of the new nanofiber material.

Hydrogen bonds are dynamic in the sense that t continuously break and reform to allow the material to dissipate high amounts of energy. Additionally, these bonds provide more stiffness that strengthens the nanofiber material. When Kevlar nanofibers are added, the team achieved almost 100% improvement in energy dissipation performance.

ALSO READ: Generating Electricity: MIT Engineers Discover New Using Tiny Carbon Particles

Testing the New Nanofiber Material

To test the new material, Azo Nano reported that the team used a laser-induced microprojectile impact in Thevamaran's lab. The system uses lasers to fire micro-bullets into the prototypes of the nanofiber materials. Thevamaran said this allowed them to conduct experiments at an observable time-scale to see how the materials responded.

They found that the new material possesses high impact resistance and like Kevlar, it is steady at very high and low temperatures. That makes the new nanofiber material ideal for a wide range of applications in extreme environments.

For now, the team is working on patenting the technology through the Wisconsin Alumni Research Foundation.

RELATED ARTICLE : Microbes Synthetic Muscle Fiber Tougher Than Bulletproof Vests Can Provide Potential Solutions in Biomedical Treatments

Check out more news and information on Material Science in Science Times.

© 2026 ScienceTimes.com All rights reserved. Do not reproduce without permission. The window to the world of Science Times.