Particle accelerators, also known as "atom smashers", use electromagnetic fields to accelerate subatomic particles like protons or electrons to extremely high speeds and energies. These particles are then directed to collide with one another or with a target material, resulting in a shower of other subatomic particles that can be studied or used for a variety of applications.

Particle accelerators have been used in scientific research to investigate the fundamental building blocks of matter, such as quarks and leptons, and to test particle physics theories. By colliding particles at high energies, physicists can recreate early universe conditions and study the behavior of matter and energy at very small scales.

Particle accelerators have also been used to create new elements that do not exist naturally on Earth, allowing researchers to learn more about the structure of the atomic nucleus.

Particle accelerators have revolutionized specific treatments in medical science with the development of proton beam therapy.

As technology advances, these machines will continue to play an important role in advancing scientific knowledge

Creating Vacuum in Particle Accelerators: Importance and Challenges

Creating and maintaining vacuum is a major aspect of particle accelerators. Vacuum is essential because it makes it possible for charged particle beams to travel through the accelerator without colliding with any gas molecules in the accelerator's environment. When such a beam comes into contact with gas molecules, it can lose energy, reducing its intensity and lifetime.

Creating and maintaining vacuum is a difficult task: vacuum systems for particle accelerators must be able to deal with a wide range of complex instrumentation and radiation issues while keeping operation and maintenance costs under control.

Optimizing Vacuum Systems for Particle Accelerators: Integration, Radiation, and Maintenance Costs

Vacuum systems must be optimized to integrate with complex instrumentation and deal with magnetic fields and radiation issues while keeping maintenance and upkeep costs at a minimum.

The vacuum system must be designed to remove any gas molecules from the chamber to create a high vacuum. Reaching a sufficiently high vacuum can be difficult because even the smallest leak or defect can allow air back into the chamber, lowering the vacuum level.

Along with being equipped with complex vacuum chamber instrumentation, vacuum systems in particle accelerators must deal with radiation issues. Radiation can be especially problematic for vacuum systems because it can impact performance and reliability. It can modify the mechanical and chemical characteristics of the materials in the vacuum system and/or increase their radioactivity level, resulting in potential failures and hazards.

On top of that, the vacuum systems must be designed to minimize operation and maintenance costs while still providing a reliable and efficient vacuum.

Agilent Technologies offers high-quality vacuum technology solutions for particle accelerators, including pumps, gauges, and leak detectors that are specifically designed for these applications. Discover Agilent Vacuum Technologies' portfolio here.

Measuring Vacuum in Particle Accelerators: Hot and Cold Ionization Gauges

Measuring vacuum in particle accelerators is essential to figuring out total gas pressure and assessing the integrity of the vacuum system. The most common methods for measuring vacuum are hot and cold ionization gauges. The density of gas atoms and consequently the pressure is calculated measuring the probability of gas ionization.

Cold cathode ionization gauges can measure vacuum conditions ranging from 1x10-2 to 10-9 mbar, whereas hot cathode gauges can measure pressure down to 10-11 mbar.

Agilent Technologies offers a variety of high-quality ionization gauges designed specifically for use in particle accelerators.

Particle Accelerators Also Leak: Importance of Leak Detection and Helium as a Tracer Gas

Although particle accelerators' operators actively work to get and maintain high vacuum levels, no chamber can be completely vacuum-tight, and as such leaks are an unavoidable challenge. Even minor leaks can have a negative impact on the particle accelerator's ultimate pressure and gas balance, resulting in lower efficiency .

Leak detection is a critical aspect of particle accelerator maintenance in order to address these issues. Helium leak detectors are the best solution for detecting leaks smaller than 10-7 mbar L/s , locating them. Helium is an ideal tracer gas for particle accelerators because it is light, inert, non-explosive, and non-toxic. Furthermore, helium is present in normal air at a concentration around 5 ppm, making it a reasonably priced and widely available option for leak detection.

Agilent Technologies: Providing Reliable Vacuum Solutions for Particle Accelerators

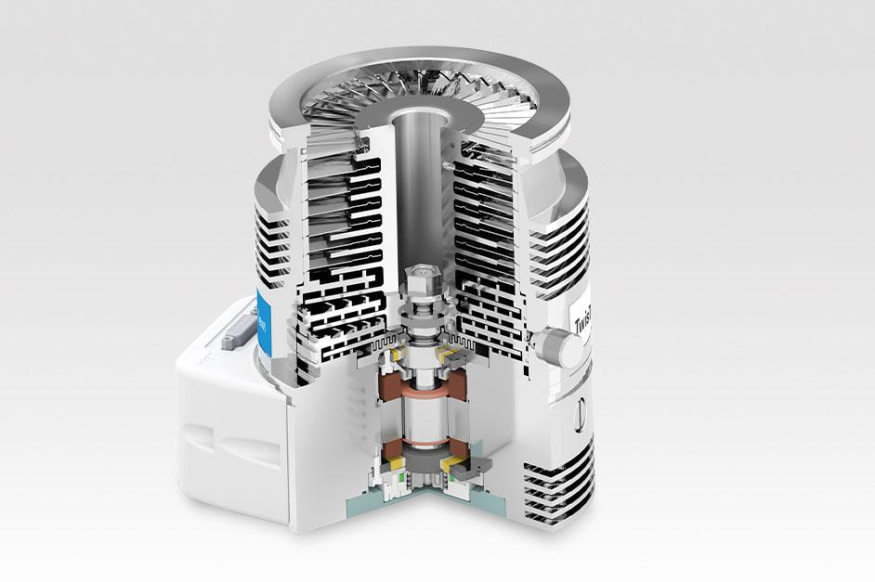

Agilent has a long history of developing cutting-edge vacuum solutions for particle accelerators. The vacuum product portfolio of Agilent includes rough, high, and ultra-high vacuum pumps (visit the Agilent Ion Pumps page ), as well as vacuum fittings, valves, and components. Because of their exceptional reliability, performance, and efficiency, Agilent's vacuum solutions are trusted by particle accelerator operators all over the world. Furthermore, Agilent vacuum products are designed for ease of use and maintenance, making them an excellent choice for particle accelerator applications.

To review, particle accelerators are an extremely versatile tool for research, and medicine, and vacuum technology is critical to their operation. High vacuum levels must be reached and maintained in order to achieve optimal accelerator performance.

Agilent Technologies offers a wide range of reliable and innovative vacuum solutions for particle accelerator operators. From creating vacuum to measuring it and detecting leaks, Agilent Technologies has the expertise and products to ensure that particle accelerators operate safely, efficiently, and accurately.

© 2025 ScienceTimes.com All rights reserved. Do not reproduce without permission. The window to the world of Science Times.