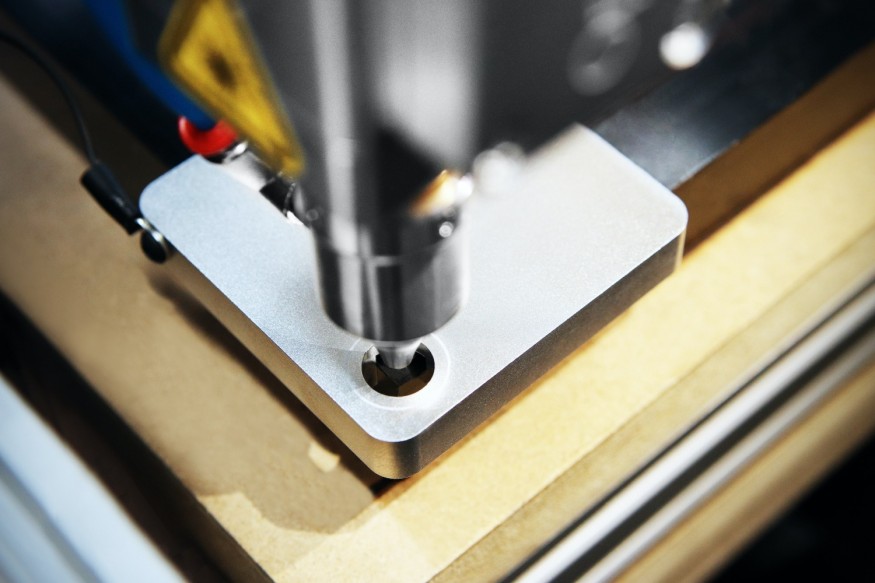

A CNC machine is an automated computer-controlled cutting tool that can produce a wide range of parts and components for different industries. It works by taking the 3D CAD model from the CAD/CAM software, then creating a code based on it. Once this code is copied into the CNC machine's memory, it then cuts through material using various tools such as lasers or plasma jets.

This process creates a detailed 2D pattern of the 3D model which can be used for further production purposes like molding or machining other components from it. So if you own or manage a small business that requires consistent production of parts and components, why not consider getting yourself one of these amazing machines? Here are 9 reasons why:

1. Accurate

Accuracy is crucial for many industries. Manufacturing, aerospace and automotive industries all rely on parts that are as precise as possible. CNC machining can be more accurate than manual machining because it uses a computer to control the machine. This means you can create parts with the same dimensions over and over again with minimal variation in size or shape between units.

2. Cost-Effective

A CNC machine is a cost-effective way to make parts for your business. The cost of using a CNC machine is much lower than other methods, and the running costs are also lower. This means that you can save money by investing in one of these machines instead of outsourcing your manufacturing needs or purchasing expensive equipment.

The efficiency of these devices also means that they provide better value for money than many other manufacturing methods: they can produce higher volumes at lower price points without sacrificing quality or reliability.

3. Versatility

If you're looking to make more than just parts, CNC machines can be used for a wide range of applications. They can be used to cut, carve and shape material into almost any shape imaginable.

CNC machines are also very versatile when it comes to materials that they can work with. Whether you need to cut through metal or wood, there is a CNC machine available that will do the job perfectly for your business needs.

4. Creativity

CNC machines are capable of creating parts that other manufacturing processes cannot. For example, if you want a part that has an intricate shape or is made from multiple materials, it would be difficult to create such a thing with traditional manufacturing methods like injection molding or stamping. However with CNC machining and CAD software, it's possible to program the machine so that it can do exactly what you need it too!

This is similar to 3D printing in some ways: both techniques allow for customizability and creativity in your designs. But unlike 3D printing (which uses plastic), CNC uses metal -- which means your final product will be stronger than anything you could produce using other methods!

5. Easy Maintenance & Repair

CNC machines are built to last, but they still need regular maintenance to keep them working at their best. It's important to regularly inspect your equipment and make sure that everything is functioning as it should. If you notice something wrong with your CNC machine, it's better to get it fixed before the problem gets worse and causes more damage or downtime for your business.

You can find local repair services that specialize in repairing CNC machines through online directories such as Yelp or Angie's List--or even by asking around at other local businesses that use similar machines (like machining shops).

6. Data Logging and Accessibility to Files

Data logging is a way to record information about the machine's performance. It can be used to track the machine's performance over time, as well as provide insight into how it operates in different situations. Data logging allows you to monitor your CNC machines for any issues that may arise and take action accordingly so you don't have downtime or lose money on repairs.

7. Faster Production Rate and Low Operating Costs

When you are using a CNC machine, producing your product will be faster than it would be if you were to manually make them. The reason for this is because the machine does all of the work for you. You can also get more done in one day because there's no need for breaks or rest periods like there would be with manual machining operations. This means that less time is spent on production and more time can go into getting other work done as well!

Additionally, operating costs are much lower with CNC machines than they would be with manual machining processes because there isn't any labor involved at all (except maybe loading materials into the hopper). All of these benefits add up really quickly over time - which makes them worth looking into if you're looking into buying one yourself!

8. Better Safety Conditions for Workers

Safety is a concern for any business, and it's important to ensure that your employees are safe at work. CNC machines are safer than other machines because they have fewer moving parts and require less maintenance. In addition, the fact that you can control the speed of the machine means you can slow it down if an operator needs more time or stop completely if something goes wrong.

When using a CNC machine, there are certain safety procedures that need to be followed in order to avoid accidents and injuries:

You should always wear eye protection when operating any type of power tool or machinery (even if it doesn't use electricity). This will protect against dust particles flying into your eyes from drilling holes or cutting metal stock into smaller pieces. It also helps keep out glare from overhead lights which could cause eye strain over time if not shielded properly by goggles made specifically for this purpose!

9. Reduced Carbon Footprint on the Environment

If you're looking for a way to reduce your carbon footprint on the environment, CNC machines are an excellent option. Using them will help save energy and reduce waste on your end. For example, if you use a CNC machine instead of hand-cutting pieces from wood or metal, it will require less power consumption because they can be programmed to operate at maximum efficiency. Also, there's no need for sanding or painting--the surface finish is already smooth and ready for use!

Another benefit of using these types of devices is that they produce less pollution than other types of manufacturing equipment such as laser cutters or milling machines (which both burn fossil fuels).

Conclusion

The CNC machine has many benefits for businesses, including the ability to produce accurate parts that require less time and money. It also allows you to be creative with your designs while maintaining safety conditions for workers because of its low operating costs and faster production rate. If you're looking for a new way to cut costs or increase productivity at your company then consider investing in one today!

© 2025 ScienceTimes.com All rights reserved. Do not reproduce without permission. The window to the world of Science Times.