In today's world, technology development and digitalisation play a key role in many industries, including packaging. In order to optimise production processes, improve logistics, and control product quality, I will explain how the digitalisation of packaging production is changing the market, how IoT and Big Data are transforming the industry, and how entrepreneurs are using these opportunities to improve their efficiency and competitiveness.

Automation of production processes, optimisation of logistics, and product quality management are the most important growth points for businesses, and they help companies become competitive enterprises, increase production efficiency, significantly improve financial performance, and reach a new level of development.

In terms of production processes, manufacturing companies try to rely on the purchase and installation of modern production equipment that allows them to automate the main stages of production. This provides high accuracy and speed of order execution, increases productivity, and reduces the amount of manual labour. Businesses are now trying to use modern systems like enterprise resource planning (ERP) systems to coordinate all business processes. It helps keep a finger on the pulse of purchasing, production, warehousing, and sales. It is good for transparency and manageability of operations. On a regular basis, businesses are optimising inventory levels of raw materials and finished goods to reduce storage costs and speed up order fulfilment.

Modern smart factories are now enterprises with fully automated (robotised) production, where all processes are controlled in real time in response to changing conditions. This is made possible through a combination of IoT technologies, big data analytics (including data from IoT devices), and various information systems for production and business process management, such as MES, ICS, ERP, EAS, and others.

Internet of Things (IoT) technology enables the creation of digital twins to obtain real-time information about various objects: transport, equipment, product status, as well as the behaviour of employees and consumers. Data collection helps build predictions and identify problems, such as the need to repair equipment early or accurately track the stages of product delivery. Big Data technology enables the collection and analysis of large volumes of data. It enables online monitoring and evaluation of the efficiency of business processes, production facilities, transport, and logistics routes.

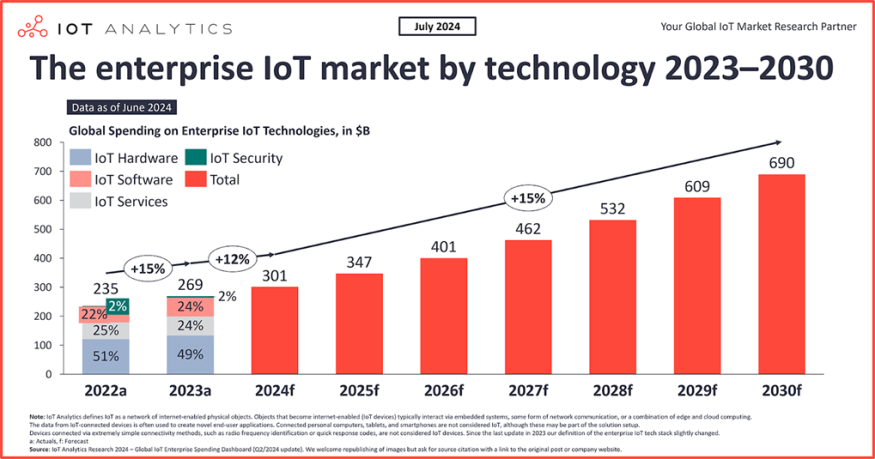

According to Statista report, the global IoT market is expected to grow to USD 1.387 billion in 2024. In addition, experts forecast the IoT market to grow at an annual rate of 12.5%.

The packaging industry is no exception and is also undergoing major changes due to the introduction of digital technologies. The Internet of Things (IoT) and Big Data are becoming essential tools that can significantly improve production processes, optimise logistics and increase product quality control. Let's look at the most important trends that are changing the industry.

First and foremost, the trend towards process automation is important. One of the main challenges of IoT in manufacturing is automation. Thanks to sensors and smart devices, IoT helps to collect and analyse data in real time, which makes it possible to control all stages of production—from raw material processing to final packaging. For example, some packaging plants are already using automated systems that monitor not only product quality but also energy consumption at different stages. This helps to optimise energy consumption and reduce the carbon footprint.

The second important aspect is improving logistics. IoT and Big Data technologies have significantly improved logistics processes. With IoT, it is possible to track the movement and status of products in real time, which minimises the risks of delays and losses. This is especially important for packaging perishable goods. We know that some companies use sensors to monitor temperature and humidity during transport, which helps to avoid product spoilage and keep packaging in perfect condition before delivery.

IoT quality control helps improve quality control at all stages of production. Big data from the lines is analysed to detect defects at an early stage, which helps reduce scrap. For example, the packaging industry is actively using machine vision systems that use cameras and AI to analyse the appearance of packaging for defects. This allows problems to be eliminated before the manufacturing process is even completed. And IoT sensors can also monitor the condition of machines and equipment on the production line. This helps identify potential malfunctions before they lead to failures, which reduces downtime and improves productivity.

Another important technology is related to demand forecasting and inventory management. Big Data and IoT systems allow companies to analyse the demand and optimise production. Collecting data from various sources helps to plan output volumes and manage inventory more accurately. This helps the company to operate with higher efficiency. For example, many packaging manufacturers integrate Big Data with ERP systems for demand forecasting and inventory management. This helps to avoid surplus or shortage of materials.

The trend towards personalisation is also affecting the issue at hand. Big Data can be used to analyse customer needs and preferences, enabling more personalised packaging solutions. This is especially relevant for manufacturers working with different market segments that require unique packaging characteristics.

For example, analysing data on consumer behaviour can help a packaging manufacturer tailor design and materials to meet the needs of specific customers, offering packaging tailored to their individual preferences.

It is important to note that digitalisation not only increases productivity but also contributes to sustainability. IoT enables waste minimisation and more efficient use of resources. Companies are implementing IoT systems to track waste and assess the environmental sustainability of production. This helps optimise recycling processes and reduce negative environmental impact.

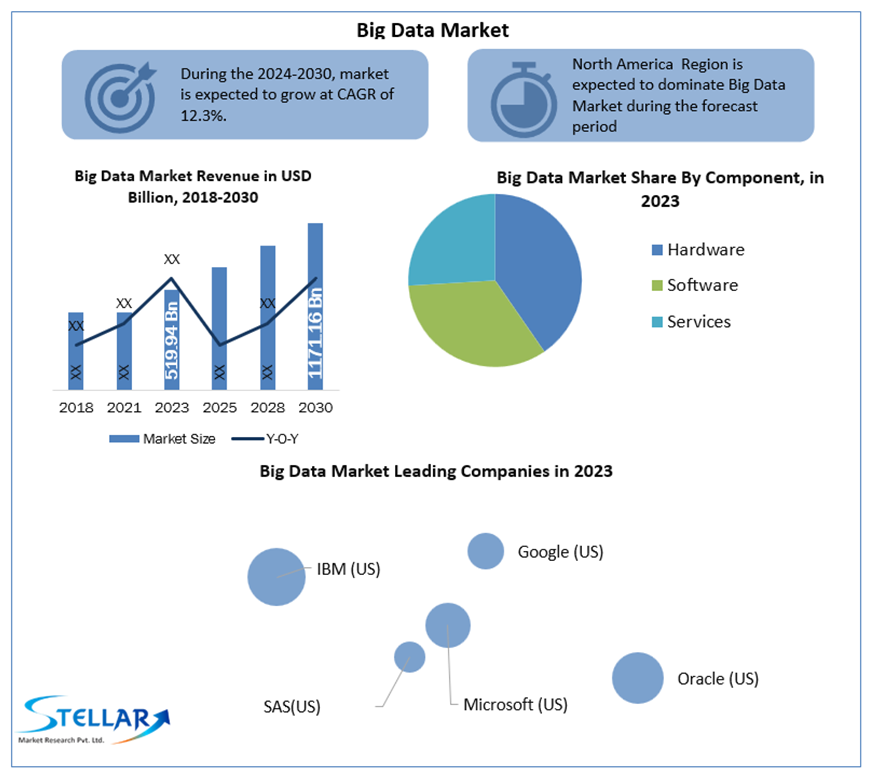

We see that the use of IoT and Big Data in the packaging industry is already having a significant impact on business. These technologies are making production more flexible, efficient, and environmentally responsible. But there are challenges along the way. Companies implementing projects using big data face a number of challenges. Most of them are related to the source data: about a third of respondents said that in their firm, more than 50% of information is entered manually, which raises questions about its quality and reliability. Despite all the difficulties, about 80 percent of Strategy Partners respondents said that the introduction of big data has an effect, and it is primarily related to faster decision-making. Another problem is cost. Processing big data is an expensive procedure. Organising the collection and storage of several terabytes of data every month may be unaffordable for entrepreneurs on its own. The cost of qualified analysts must be added to this.

Nevertheless, companies that implement digital solutions gain competitive advantages such as lower costs and improved product quality. In the future, we can expect digitalisation to gain momentum, offering more and more innovative solutions for the packaging industry. Digitalisation in the packaging industry is thus becoming not just a trend but a key prerequisite for successful competition and development. Those companies that already rely on innovation today will not only be able to fulfil current market needs but also be one step ahead of future trends and developments. Investments in digitalisation pay off not only financially but also strategically, opening up new opportunities for growth and development.

© 2025 ScienceTimes.com All rights reserved. Do not reproduce without permission. The window to the world of Science Times.