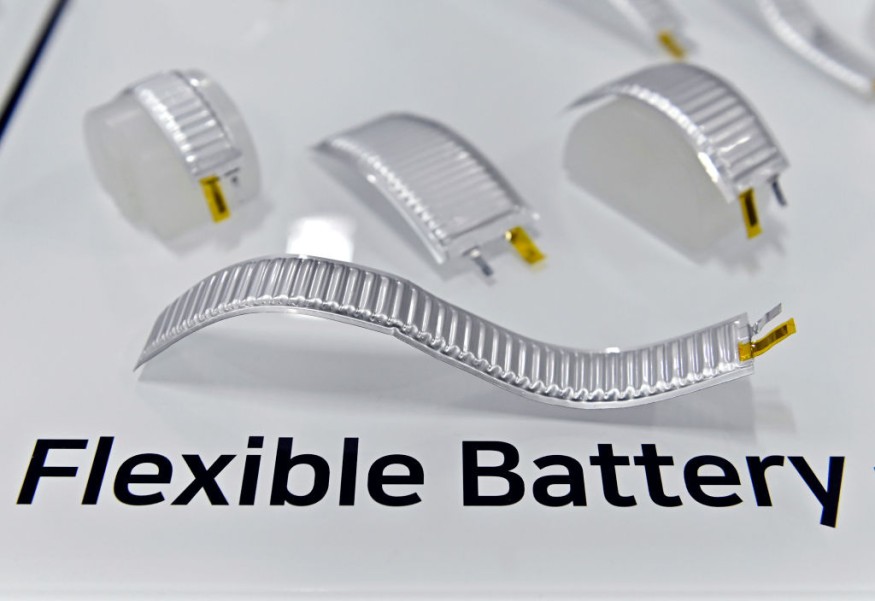

Nanoengineers produced the first printed flexible battery that is lightweight and rechargeable. Zinc batteries could power anything from wearable cameras to solar cells and other kinds of electronics. In Advanced Energy Products, the study from the University of California San Diego shows promising results.

Combining a hyper-elastic polymer material made of isoprene, one of the key ingredients in rubber, and polystyrene, a resin-like part, the researchers made the printed batteries versatile and stretchable. The material known as SIS helps the batteries extend either way, without suffering damage, to twice their scale.

Zinc silver oxide combined with SIS is the ink used to print the batteries. While zinc batteries have long been in use, they are usually non-rechargeable. To allow them rechargeable, the researchers applied bismuth oxide to the batteries.

The researchers' prototype battery has around 1/5 the capacity of a rechargeable battery for hearing aids. Yet it is 1/10 as dense, cheaper, and uses commercially usable products. Two of these batteries are needed to power a 3V LED.

Efficient?

Researchers are also working to boost the efficiency of the battery. The next moves are to extend the use of the technology to other uses, such as solar and fuel cells, and to control multiple forms of electronic devices utilizing the battery.

Researchers used traditional screen printing techniques to create the batteries, which significantly cuts down the technology's costs. Typical one-battery supplies cost just $0.50, that's the $5.00 equivalent of a similar commercially usable rechargeable battery.

Batteries can be printed directly on fabric or materials that enable the skin to be adhered to by wearables. You may also print them as a strip to power a system that takes more electricity. They are durable for an extended period and can be worn.

A molecule named bismuth oxide, which is incorporated into the batteries' zinc electrodes, prolongs devices' existence and helps them recharge, is the main component that allows the batteries to rechargeable. The addition of bismuth oxide to zinc batteries is the standard industrial procedure for enhancing efficiency, but there has not been a comprehensive scientific reason for why until recently.

UC San Diego nano engineers led by Professor Y. Shirley Meng released comprehensive molecular research last year that explores this topic. Their electrodes react with the fluid electrolyte within the battery as zinc batteries discharge, creating zinc salts that dissolve into a solution.

This also short-circuits the battery. The electrode is protected from losing zinc to the electrolyte by introducing bismuth oxide. This means the batteries continue to run and can be recharged.

Better Manufacturing

But AgO hasn't been used before in a screen-printed battery, since it is incredibly oxidative and rapidly degrades chemically. Researchers in Wang's lab at UC San Diego was able to pinpoint an ink solution that renders AgO feasible for printing by checking different solvents and binders.

Consequently, if the inks are primed, the battery can be printed in just a few seconds. In just a few minutes, it is dry and ready to use. In a roll-to-roll method, the battery could also be manufactured, which would improve the pace and allow output scalable.

The batteries are written on a thermodynamically stable, elastic polymer film with a high melting point that can be heat-sealed (about 200 degrees C or 400 degrees Fahrenheit). A stacked screen-printed sheet is each created by current collectors, the zinc anode, the AgO cathode and their accompanying isolators.

The team is also working on next battery cycle, looking for even lower impedance. These smaller, quicker charging solutions can be used in 5G devices and soft robots that involve high power and versatile and compact form factors.

"Understanding the scientific mechanism to do this will allow us to turn non-rechargeable batteries into rechargeable batteries - not just zinc batteries but also for other electro-chemistries, such as Lithium-oxygen," said Meng, who heads the Sustainable Power and Energy Center at the UC San Diego Jacobs School of Engineering.

ALSO READ : First Time in the World: Demonstration of Ultra Pressure Sensor Attached to the Fingertips

Check out more news and information on Technology on Science Times.