It all starts with a three-dimensional model, 3D printers and a suitable material. The whole 3D printing exercise takes advantage of the additive manufacturing process that depends on digital files. This means that a 3D solid object is created by laying down successive material layers until the process is complete. Well, that being said, the article will focus more on basic 3D printing, its advantages and how it works.

This additive manufacturing covers various technologies and processes, offering a full spectrum of capabilities to produce different products using different materials. So, are you looking forward to implementing 3D printing in your manufacturing business? Get 3D printing quotes and enjoy the smartest manufacturing solution at Sculpteo 3D printing company. We offer amazing offers together with professional printing services. Therefore, don't hesitate to contact us if you need an online 3D printing service for your individual products, short-run manufacturing (small or large-scale industry) or on-demand prototype production.

Thanks to companies like Sculpteo, you don't have to own a 3D printer to get a three-dimensional product. We print your order and ship it to you within the stipulated time. Customers can choose items other users designed or submit their designs for printing.

3D Printing: What is it?

3D printing technology is termed to be bigger than the internet. Some people believe it, while others know that it is an extraordinary hype that came to be around this technological era. So, what is this 3D printing and how does it work?

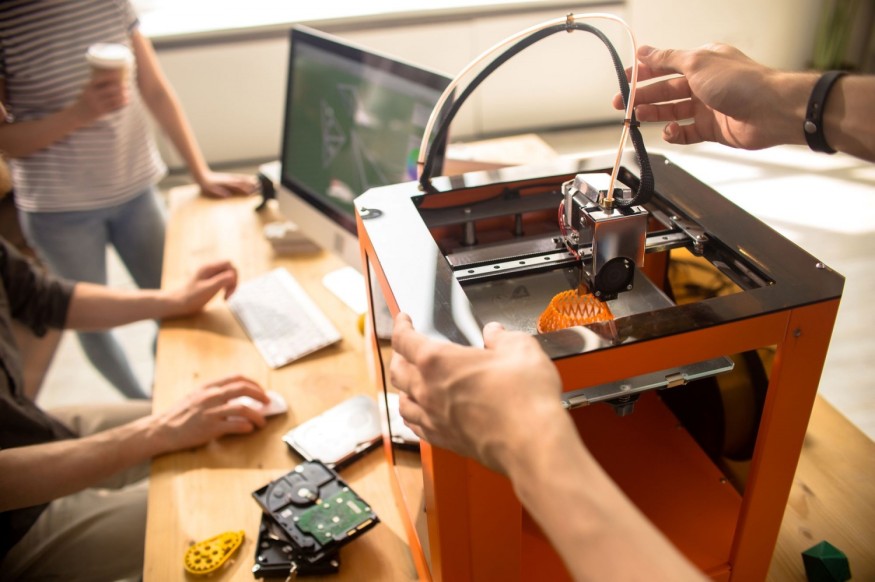

A basic definition of 3D printing is a process (manufacturing) where thin-sliced material is laid down to form a 3D solid object layer by layer. The process is called additive since the item is built from scratch compared to a process where materials are milled, cut, machined off or drilled (Subtractive process).

The process is carried out with a 3D printer which comes in different shapes and sizes. However, despite the different materials used by 3D printers, they all share one thing: the ability to turn three-dimensional data (in a digital file) into a solid physical item.

Importance of 3D Printing

3D printing plays an important role when it comes to business and industrial design. Designers can now turn concepts into prototypes or three-dimensional models and still have room to implement any design changes. On the other hand, manufacturers, thanks to 3D printing, can produce products on demand, avoiding warehouse fees or reducing space and improving inventory management.

People can now access parts and items that otherwise would be inaccessible, especially in remote areas. Unlike the subtractive manufacturing technique, 3D printing (additive methods) can save lots of materials and money from a practical standpoint. The best part is that people can now print anything in their homes, including complex 3D objects like electronic devices and parts.

3D Printing: How Does it Work?

Similar to traditional printing, 3D printing uses a series of technologies. One of the most used technology is Stereolithography. It is another additive manufacturing technology that falls under the Vat Photopolymerization category together with Digital Light Processing (DLP). A 3D object is made by selectively curing a layer-by-layer polymer resin using a UV (ultraviolet) laser beam. The laser beam will trace the pattern's cross-section already on the surface of the resin to make the three-dimensional object.

The pattern is cured and solidified by the UV laser light after minutes of exposure. This technique is one of the best when it comes to producing smooth surface and fine details, suitable for making medical appliances and jewelleries and prototyping.

In material jetting, heat or ultraviolet light is used to harden metals, wax or photopolymers, creating parts one layer after the other. It offers high accuracy, a smooth surface finish and excellent details. The most famous material jetting technique include Drop-on-demand (DOD) and NanoParticle jetting (NPL).

3D printers use various materials (depending on the technology used), including but not limited to plastics, ceramics, metals (Aluminium, Titanium and stainless steel), glass, polymer and plaster.

Takeaway

Designers can use 3D printing techniques to develop product prototypes and models. Besides that, the technology is used to make final products in different industries like automotive, fashion and construction. There is plenty of 3D printers available for small business and homes, but they are considered a bit pricey, which is why companies like Sculpteo exist. For a nice three-dimensional object or part, contact us at any time.