The problem of diaper waste is substantial, with roughly 300,000 diapers being discarded globally every minute. Scientists from the Karlsruhe Institute of Technology (KIT) in Germany and Xi'an Jiaotong University in China have potentially found a solution: they developed a method that can transform a key diaper component into recyclable liquid in just five minutes.

This innovative approach harnesses ultraviolet (UV) light to break down the crucial diaper component without the need for additional chemicals, using only water. They targeted superabsorbent polymers, which are responsible for liquid absorption and are also present in various hygiene and medical products like bandages.

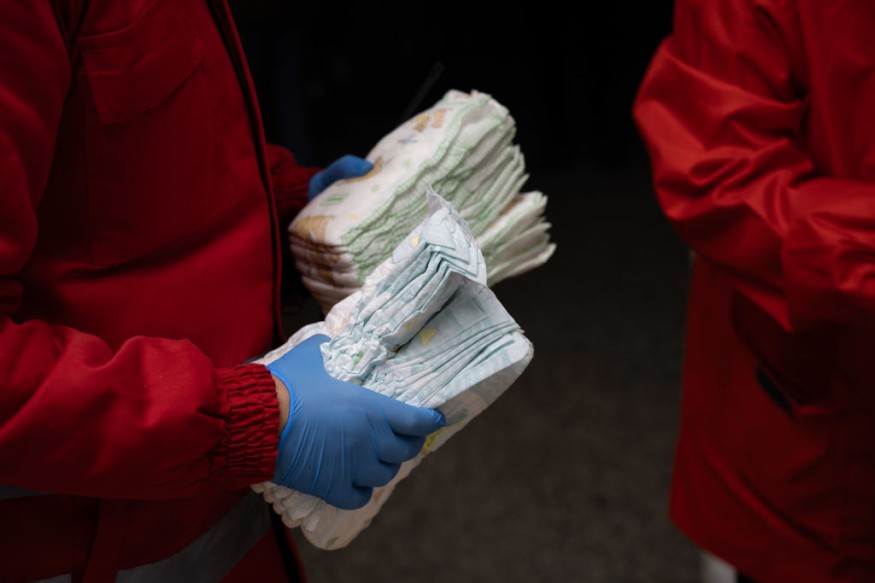

Just Add Water: Recycling Diaper Waste

Professor Pavel Levkin, a specialist in multifunctional materials systems at KIT, explained that the UV light breaks the chains connecting the polymers, making them so loose that they transform into liquid fibers when placed in water. The researchers found that this method is about 200 times faster than using acids, which were previously explored for breaking down these polymers.

Although acids can dismantle polymer chains, it's a challenging and costly process, leading to the disposal of around two million tons of superabsorbers annually, either through burning or landfill.

In the new process, published in ACS Applied Materials & Interfaces, the diaper liners were soaked in water and exposed to a 1000W UV lamp after being removed from the diapers. Within minutes, the material transformed into a liquid that could be collected efficiently.

While UV light is known for degrading materials by affecting the chemical bonds in their surface molecules, the speed and effectiveness of the degradation can vary depending on the material. The researchers applied their knowledge of UV light reactions, accelerating the recycling process.

The resulting substance from the recycling procedure has versatile applications, such as serving as a thickening agent for water-based dyes or as a component in various adhesives, avoiding landfill disposal.

Although the superabsorber is just one part of a diaper, this development marks progress in addressing plastic pollution issues, and the team believes that scaling up the process is feasible, significantly reducing environmental pollution and promoting sustainable polymer utilization.

A House Made From Recycled Diapers

In Indonesia, researchers have developed a novel method of using shredded disposable diapers to construct affordable and sustainable homes.

This innovative approach incorporates approximately 2 cubic meters of used diapers into the structural elements of a single-story house, addressing both the challenges of waste management and the need for low-cost housing, particularly in rapidly urbanizing regions like Indonesia.

The research demonstrates that repurposed diapers can effectively replace up to 27% of traditional materials used in load-bearing structural components, without compromising structural integrity. Shredded diapers can also replace up to 40% of the sand used in non-structural components, such as wall partitions and garden paving blocks.

While this approach holds promise, challenges such as separating plastic components from organic fibers and existing building regulations may impact its environmental sustainability. Chemist Christof Schröfl suggests exploring alternatives to disposable diapers, focusing on more sustainable and less frequently discarded materials.

RELATED ARTICLE:

Chemical Recycling Repurposes Diapers into Adhesives Removing Millions of Sodden Diaper Wastes

Check out more news and information on Chemistry in Science Times.