Laser engraving has transformed our ability to create and customize, from perfectly personalizing gadgets to designing complex jewelry. But have you ever considered how this amazing technology works or why it's so safe, even with high-powered lasers?

An essential component of modern industry and personalization, laser engraving combines art and technology. Laser engraving precisely etches designs, logos, and text onto wood, metal, glass, and leather using focussed beams of light. Because laser engraving is more exact than hand tools, intricate designs previously unattainable are made possible.

These powerful machines raise the question of whether they are safe for use. Modern laser engraving systems, like the Creality Falcon2 Pro, protect operators from intense light and fumes through protective enclosures, sensors, and ventilation systems. This article will discuss the physics of laser engraving, along with its exact technology and safety developments. For both experts and hobbyists, knowing these machines may unleash almost limitless imagination.

How Laser Engraving Works: Precision in Action

Laser engraving is basically a concentrated beam of light directed onto the surface of a substance, vaporizing or etching the top layer to create detailed drawings. Excellent accuracy made possible by this technology lets users create complex patterns, logos, or text on many materials—including wood, metal, glass, and plastic. The basic ideas of laser engraving depend on several important parts:

- Laser Source: Any laser engraving machine is built upon its laser source. Each is designed for particular materials and engraving needs. Common varieties include CO2 lasers, fiber lasers, and diode lasers. Fiber lasers are more appropriate for metals and polymers, while CO2 lasers shine, especially in engraving organic materials like wood and leather.

- Optics and Focusing Mechanism: Optics and Focusing Mechanism: Remarkably precisely, a series of mirrors and lenses guides and focuses the laser beam. Users can maximize the intensity and quality of the engraving by varying the focal length, therefore ensuring that minute details are precisely preserved.

- Material Interaction: When the laser beam contacts the surface of the material, its concentrated energy causes controlled melting or vaporization. Depending on the settings—power, speed, and frequency—this produces either subtle etchings or profound engravings.

- Control Software: Modern machines have sophisticated software that lets users plan, alter, and run digital engraving jobs. These systems guarantee consistency and accuracy by turning the computer drawings into exact directions for the machine.

- Cooling Systems: Particularly in continuous operations, laser engraving generates large heat. Often used water or air, integrated cooling systems help to prevent overheating of the equipment, therefore guaranteeing lifetime and performance.

The non-contact nature of laser engraving makes it unique, as it prevents tool wear and tear. This benefit makes the machine perfect for high-precision work, as it increases its durability and guarantees output consistency.

Unmatched Versatility Across Materials and Applications

The ability of laser engraving equipment to operate on a broad spectrum of materials is well-celebrated. Their adaptability has helped them be used in sectors from manufacturing and art to education and personal endeavors. Several often used materials fit for laser engraving are:

- Wood: Wood is ideal for designing complex designs on furniture, house décor, and hand-made gifts.

- Acrylic: Acrylic's smooth, polished appearance makes it perfect for displays and signage.

- Metal: Used in industrial environments for durable surface serial numbers, barcodes, and logo engraving.

- Glass: This material is frequently used for etching delicate motifs onto trophies, drinkware, and decorative accents.

- Plastics: Frequently used in electronics for marking components and housings.

Every material responds differently to laser energy; hence, power, speed, and focus levels must be changed. Whether it's making personalized keepsakes or branding industrial components, this flexibility guarantees that laser engraving equipment satisfies the needs of many projects.

Safety First: Innovations in Enclosed Laser Machines

Although laser engraving machines are powerful, their operation calls for safety precautions. By adding creative elements into contemporary enclosed machines, manufacturers have given user safety a top priority and let even beginners run them with confidence. Here is a closer view of these safety elements' functioning:

1. Enclosed Workspaces

Safety is the first design consideration for enclosed laser engravers. These devices have wholly sealed chambers containing the engraving operation, preventing unintentional exposure to the laser beam. This construction guarantees that users may operate the machine without direct laser contact.

2. Ventilation and Fume Extraction

The vaporization process during laser engraving can produce hazardous fumes, mainly when working with plastics or coated materials. Enclosed machinery often includes built-in exhaust fans or ventilation systems to absorb and filter these emissions, maintaining air quality while shielding consumers from harmful particles.

3. Interlock Mechanisms

Enclosed machinery includes the interlock system, which instantly shuts off the laser if the enclosure is opened during operation. This crucial safety precaution shields the operator and onlookers from unintentional exposure to the intense laser beam.

4. Protective Glass or Filters

Enclosed equipment's viewing windows are usually composed of specialized glass or plastic filters that block dangerous laser radiation wavelengths. This lets consumers track the engraving process without risking eye damage.

5. User-Friendly Controls and Alerts

Modern laser engraving machines have easy control panels and safety alerts that guide users through the setup and operation process. Certain types include built-in sensors that inform the operator about possible hazards, such as overheating or incorrect material placement.

Key Benefits of Enclosed Laser Machines

The transition from open-frame designs to enclosed laser engravers has revolutionized the industry, offering several benefits beyond safety:

- Noise Reduction: Enclosed designs dampen operational noise, creating a quieter work environment—a crucial advantage for home users and small workshops.

- Compact Footprints: Enclosed machines often have a more compact design, making them suitable for smaller spaces without sacrificing functionality.

- Enhanced Precision: The stable, enclosed environment minimizes external factors like dust and vibrations, ensuring higher accuracy in engravings.

Unlocking Creativity: Practical Applications

The precision and safety of modern laser engraving machines have unlocked endless possibilities for users across different fields. Some practical applications include:

- Customization and Personalization: Laser engravers are perfect for creating personalized items such as jewelry, phone cases, and photo frames. The ability to etch intricate designs ensures high-quality, one-of-a-kind products.

- Industrial Marking: Industries rely on laser engraving to mark serial numbers, barcodes, and logos on parts and tools. The process ensures durability and readability, even in harsh environments.

- Educational Tools: Schools and maker spaces use laser engravers to teach students about design, engineering, and technology. The enclosed machines' safety features make them ideal for learning environments.

- Prototyping and Manufacturing: Laser engraving accelerates prototyping by allowing designers to create detailed parts and models quickly. This capability supports innovation and speeds up the product development cycle.

- Art and Design: Artists and designers use laser engraving to push creative boundaries, producing intricate works on unconventional materials like slate, bamboo, and textiles.

Creality Falcon2 Pro: A Cutting-Edge Laser Engraver for Every Creator

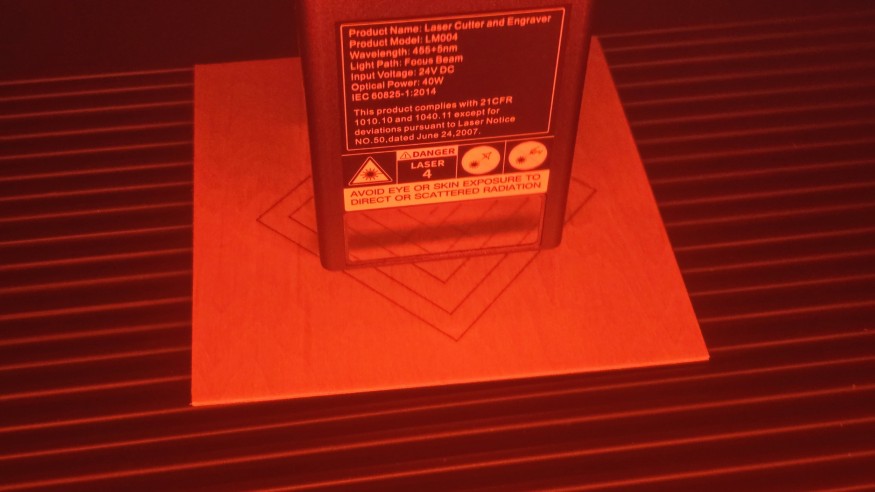

The Creality Falcon2 Pro is a game-changing laser engraver and cutter designed to elevate creativity across various fields. Whether you're a hobbyist exploring the art of laser engraving or a seasoned professional seeking a reliable tool for intricate projects, this cutting-edge machine delivers exceptional performance and unmatched versatility. Packed with state-of-the-art features, it combines speed, precision, and safety to ensure every project achieves outstanding results.

Its user-friendly interface and advanced technology make it accessible for beginners while offering powerful functionality that meets the demands of professionals. From personalized gifts and artistic designs to large-scale production tasks, the Falcon2 Pro adapts effortlessly to various applications.

Key Features:

- Exceptional Speed and Power:

- Engraving speed of up to 25,000mm/min.

- Dual laser modules (22W and 40W) for versatile applications.

- Innovative Pilot Technology:

- Built-in top camera for precise alignment.

- Visual assistance for full-frame functionality.

- Comprehensive Safety Features:

- FDA Class 1 certification with a 360° transparent cover for complete visibility.

- Lid-open safety stop to prevent laser leakage.

- Intelligent flame, dirt, and airflow monitoring systems.

- Durable and Practical Design:

- Sturdy aluminum structure for long-term use.

- Metal drawer design for easy debris collection and workspace organization.

- Enhanced Compatibility and Flexibility:

- Compatible with LaserGRBL and LightBurn software.

- Supports offline operation via TF card.

- Works with various materials, including wood, acrylic, leather, and fabric.

- Large Work Area:

- Generous engraving area of 400x415mm for expansive projects.

- Advanced Cutting Capabilities:

- Cuts a 20mm basswood board in one pass (40W module).

- Cuts a 10mm basswood board in one pass (22W module).

Perfect for both hobbyists and professionals, the Falcon2 Pro combines efficiency, safety, and precision to unlock endless creative possibilities.

How to Use Creality Falcon2 Pro Laser Engraver

The Creality Falcon2 Pro is a versatile enclosed laser engraver and cutter designed for both beginners and experienced users. To get started, follow these steps:

1. Unboxing and Assembly:

- Unboxing: Carefully unpack the machine, ensuring all components are present.

- Assembly: Follow the instructions in the user manual to assemble the cover, attach the laser module, and connect the fan and light using the provided tools.

2. Software Installation:

- Connection: Connect the Falcon2 Pro to your computer via the included USB cable.

- Software: Install compatible software such as LightBurn or LaserGRBL to design and control your engraving projects.

3. Calibration:

- Initial Setup: Perform necessary calibrations within the software to ensure optimal performance.

- Camera Alignment: Utilize the built-in camera for precise design alignment and real-time previews.

4. Material Preparation:

- Selection: Choose appropriate materials like basswood, plywood, bamboo, cardboard, leather, or acrylic.

- Testing: Conduct test engravings on scrap pieces to determine optimal settings for power and speed.

5. Safety Measures:

- Eye Protection: The enclosed design filters harmful laser light; however, always ensure the cover is properly closed during operation.

- Ventilation: Use the built-in fan to direct fumes away, preferably towards a window or through an air purifier.

- Fire Safety: Keep a CO₂ fire extinguisher or fire blanket nearby and be aware of the machine's emergency stop features.

6. Operation:

- Design: Create or import your design into the chosen software.

- Settings: Adjust the laser's power and speed settings based on the material and desired outcome.

- Execution: Start the engraving or cutting process, monitoring the machine as it operates.

7. Maintenance:

- Cleaning: Regularly clean the laser lens and work area to maintain performance.

- Inspection: Check for signs of wear and perform routine maintenance as outlined in the user manual.

For a visual guide on setting up and using the Falcon2 Pro, you may find the following video helpful:

By following these steps, you'll be well on your way to creating precise and intricate designs with your Creality Falcon2 Pro laser engraver and cutter.

Combining Precision and Safety for a Brighter Future

Laser engraving machines have come a long way, evolving from niche tools to versatile, user-friendly devices. These machines are now essential in many different fields thanks to developments in safety elements and precise technologies. Their versatility in working on several materials, combined with the extra security of enclosed designs, guarantees accessibility for both experts and amateurs.

The Creality Falcon2 Pro, with its cutting-edge features like FDA Class 1 safety certification and pilot technology for precise positioning, exemplifies how advanced laser engravers cater to modern creators. Its innovative design ensures maximum productivity without compromising safety, making it a standout choice for professionals and hobbyists alike. You can purchase the Creality Falcon2 Pro with code FNPALL10 (not combinable with page discounts) and check out our New Year discounts.

As the technology develops, future laser engraving will offer even more accuracy, efficiency, and creative possibilities. Laser engraving provides a strong, safe, and dependable solution, whether your project is artistic, corporate labeling of industrial components, or a hobbyist investigating innovative ideas.

Modern laser engraving machines are pillars of precise manufacturing and artistic expression. They combine scientific ideas with creative safety precautions to demonstrate the ideal fusion of technology and imagination.